- كتب بواسطة: Sharifah Noor Sahila Syed Jamal

- المجموعة: PENYELIDIKAN SLIDER

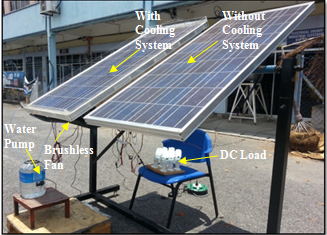

Automatic Cooling System Using PIC 18F4550 For Solar Panel

|

|

|

|

|

|

|

Solar photovoltaic (PV) power generation is an attractive technique to reduce consumption of fossil fuels and as a renewable energy. The temperature of PV panel increases when it absorbs solar radiation, causing a decrease in efficiency. The power and efficiency of PV panel usually falls at the rate of ~0.5 %/˚C and ~0.05 %/˚C respectively as increase of ambient temperature. To actively cool the PV panel, an automatic solar cooling system is design by using DC brushless fan and DC water pump with inlet/outlet manifold. This system is needed for uniform airflow and water flow distribution at the back and front surface of PV panel. Temperature sensors were installed on the PV panel to detect temperature of PV. PIC 18F4550 was used to control the operation of DC brushless fan and water pump depending on temperature PV panel. This controller system is an intelligent system because it will run the DC hybrid cooling system when the temperature of PV panel reaches setting level that detected by temperature sensors automatically and avoid waste electrical energy.

The maximum voltage output, maximum current output and maximum power output and every change temperature on PV panel were shown to compare the performance with and without cooling system. The results showed that the PV panel with cooling system is higher in term of power output compare to without cooling system. The higher efficiency of PV panel, the payback period of the system can be shorted and the lifespan of PV panel can also be longer. |

|

|

Keywords:PV panel, DC hybrid cooling system, PIC controller, Temperature, Power Output |

|